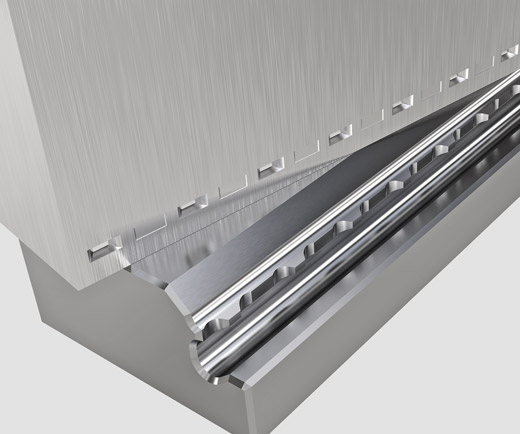

Form fit makes it possible

The form fit produced by the stamping station offers many advantages. Due to the minimum clamping edge of only three millimetres, the customer is able to reduce his material costs. Furthermore, highest chip volumes can be realized, which in turn leads to time savings and cost reductions as well. The lower clamping pressure, which is sufficient due to the form fit, causes less deformation on the workpiece and ends in better results in component quality. The very good accessibility on the workpiece, makes it possible to use shorter tools, which leads to higher process reliability and better results. The proven tooth contour consists of a holding tooth and a depth stop. Components can also be reproducibly stamped and clamped in series. By using a centre marking, the workpieces can be inserted in the machine with precise positioning even without disturbing stops.

- Minimum clamping edge

- Low clamping pressure in the vice

- Best accessibility

- No annoying stops in the machine

+49 4207 6887-0

+49 4207 6887-0 Contact form

Contact form