250219_Stellenanzeige_ADM_Südbayern

Deine Rolle:

- Kundenbetreuung mit Kompetenz: Biete erstklassigen, serviceorientierten Support für unsere Kunden in deinem Außendienstgebiet.

- Verkaufstalent gefragt: Führe Verkaufsverhandlungen und berate Kunden kompetent, um Lösungen zu finden, die genau passen.

- Netzwerk ausbauen: Erweitere deinen Kundenstamm, gewinne neue Interessenten und steigere die Bekanntheit unserer Produkte durch Beratungen, Präsentationen und Messeauftritte.

- Eigenständige Planung: Organisiere deine Termine selbstständig und strukturiert und übernimm dabei Eigenverantwortung.

- Ziele erreichen: Setze gemeinsam mit der Vertriebsleitung die Unternehmensstrategie zielstrebig und zuverlässig um.

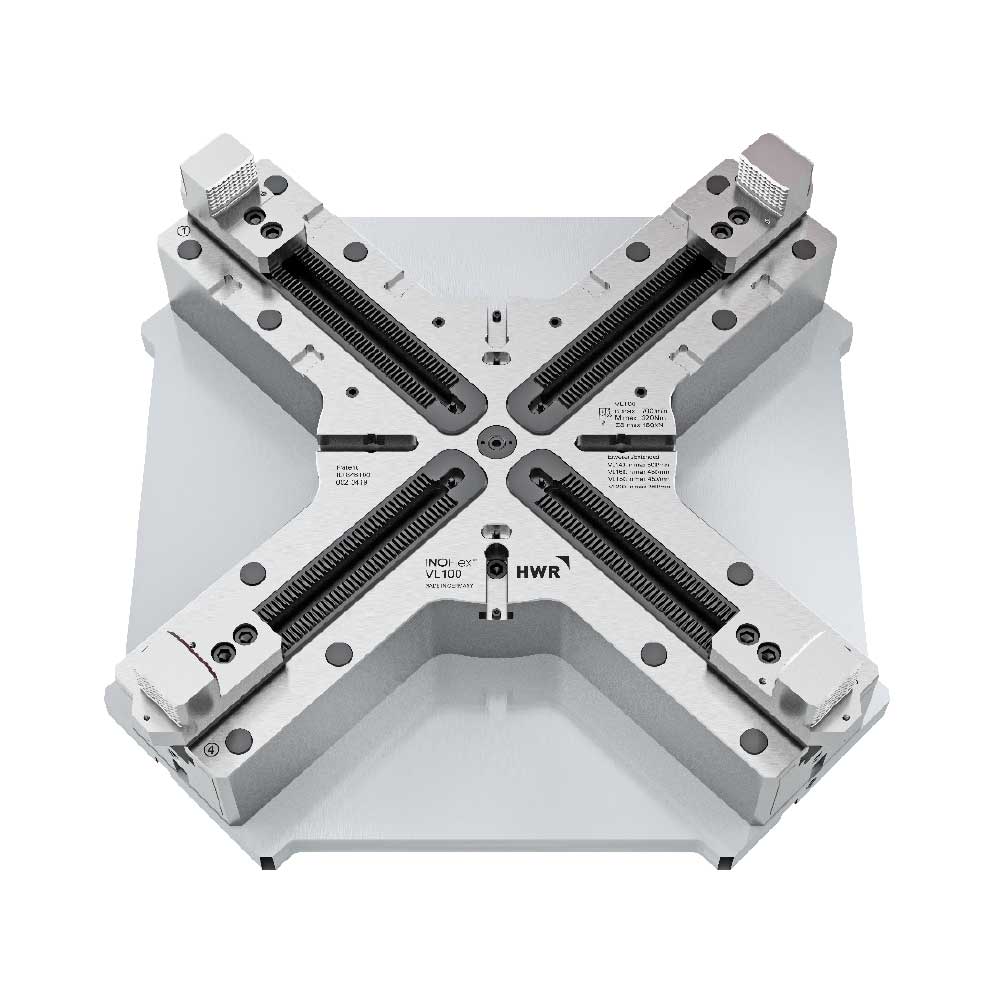

- Produktpräsentation: Demonstriere und präsentiere unsere Produkte und Lösungen überzeugend.

- Anfragen bearbeiten: Erfasse und erstelle Anfragen in Kooperation mit Konstruktion & Innendienst für unsere maßgeschneiderten Spannlösungen.

- Kommunikation und Lösungsfindung: Vermittle klar kundenspezifische Anforderungen an die Fachabteilungen und sorge für eine zuverlässige und lösungsorientierte Umsetzung.

Was wir erwarten:

- Fachliche Kompetenz: Du bringst eine abgeschlossene technische Ausbildung in der spanhebenden Bearbeitung mit.

- Weiterbildung zählt: Eine Weiterbildung zum Betriebswirt, Meister oder Techniker wäre ideal.

- Profi am Werk: Du hast bereits im Vertrieb gearbeitet und weißt, wie unsere Branche tickt.

- Zielstrebig und belastbar: Du bist zielorientiert, belastbar und bringst ein hohes Maß an Teamfähigkeit, Struktur und Konsequenz mit.

- Der Verkauf liegt dir: Du bist ein Macher-Typ mit positiver Ausstrahlung und einer Leidenschaft für den Verkauf.

- Digital affin: Im Umgang mit gängigen Office-Anwendungen bist du sicher.

- Kommunikationsstärke: Du kommunizierst stilsicher und kundenorientiert auf Deutsch.

- Positive Einstellung: Du bist gut gelaunt, motiviert, gut organisiert und zeichnest dich durch Zuverlässigkeit aus.

Wir bieten Dir:

- Langfristige Sicherheit: Freue dich auf ein unbefristetes Arbeitsverhältnis in einem wirtschaftlich gesunden und wachsenden Unternehmen.

- Gerechte Bezahlung: Wir belohnen deine Leistung angemessen, mit einem erfolgsbasierten Anteil.

- Mehr als nur Geld: Vermögenswirksame Leistungen und attraktive Mitarbeiterrabatte durch unser „Corporate Benefits-Programm“.

- Flexibilität und Mobilität: Nutze die Vorteile flexiblen und mobilen Arbeitens mit modernen Geräten wie iPad, iPhone und Laptop.

- Firmenwagen: Genieße die Freiheit eines Firmenwagens mit Tankkarte, auch zur Privatnutzung.

- Professionelle Unterstützung: Wir sorgen für eine professionelle Einarbeitung und Schulung und bieten dir dauerhafte Unterstützung durch unser erfahrenes Team.

- Deine Ideen zählen: Bringe eigene Ideen ein und profitiere von flachen Hierarchien in einem kollegialen und zielorientierten Arbeitsumfeld.

- Mehr als nur Arbeit: Freue dich auf Firmenevents, Dienstradleasing, HWR Teamwear.

+49 4207 6887-0

+49 4207 6887-0 Contact form

Contact form