Devising simple, effective & intelligent clamping solutuons is a challenge that requires creativity, experience & self-confidence.

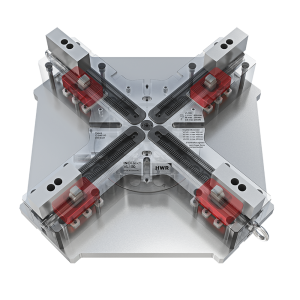

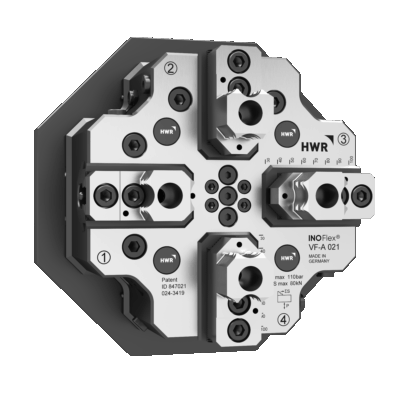

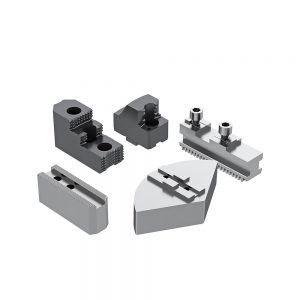

We, as an HWR team, stand for the courage needed to take on near-impossible things. Driven by the constant challenge of providing innovative enhancements, we have devised the INOLine® product range and produce them in quality and precision. This path will lead us to other new products. INOFlex®, INOZet®, INOTop® are products meeting the constantly intensifying requirements in turning and milling work. Up-to-the-minute machine tools need universally deployable clamping systems to come up with maximum accuracies. Both cubic and round components are clamped with the INO® clamping system in an optically concentric manner. As a result, your components are manufactured at low cost. In particular when clamping deformation-susceptible components, excellent results can be achieved with the INO® clamping systems.

INOLine® – clamping technology

with know-how!

The greatest benefit our customers have aside from our turning and milling products is our service and track record in clamping technology which extends over 3 decades. Whether standard or customised solutions are involved, our entire HWR team is there to prepare the solution to fit your requirements for the clamping tasks. We are more than willing for our abilities to be put to the test and for our staff and products to be available on the spot at your machine for your clamping tasks.

+49 4207 6887-0

+49 4207 6887-0 Contact form

Contact form